Day :

- Materials Science and Engineering | Nanomaterials and Nanotechnology | Materials for Energy Applications | Biomaterials and Medical Devices | Metals, Mining, Metallurgy and Materials

Location: Wien 2

Chair

Bruce S Hudson

Syracuse University, USA

Session Introduction

A Manulyk

Antech Services Inc., Canada

Title: New electron-beam equipment and technologies for production of advanced materials using vaccum melting and evaporation methods developed at SPE “ELTEKHMASHâ€

Time : 12:15-12:45

Biography:

Alexander Manulyk is a Materials Science professional. He has over 30 years of wide-ranging experience in welding, heat treatment, melting, coating, composites, process metallurgy, plasma metallurgy, electron-beam and lasers technologies. His 17 publications, Certificates of invention and patents, numerous conference presentations demonstrate my success and accomplishments during these years. He has completed his Graduation at “Kiev’s State University” in the Department of Physics of Materials & High-Temperature Super Conductivity and Postgraduation courses in Electric Welding Institute in the Department of Plasma Metallurgy. He is a Professional Engineer and has a Master’s degree in Meutallrgy/Materials Sciences based on the evaluation done by this organization. He is also a licensed Chartered Engineer of IMMM (Mining, Material, and Metallurgy Institute) in the UK.

Abstract:

At the end of 60-th beginning of 70-th years in the Electric welding institute named after Paton (National Academy of Science) in Ukraine, the new method of thick (more than 50 microns) film coatings was developed through rapid electron-beam evaporation and further condensation in vacuum for metals and non-metals materials. However, until recently unique opportunities of this method for obtaining of absolutely new materials like high-hardening, micro-layer, micro-porous types, gradient function materials haven't been explored. The recently founded research and production enterprise "ELTECHMASH" in Vinnitsa (Ukraine) elaborates new ways for evaporation and condensation processes, as well as widening mentioned above application in the practical field. Today our company develops such directions of electron-beam technology as; Electron-beam deposition of coatings; Electron-beam deposition of wear-resisting and high-hardening coatings on the tools, stamps, press- form, etc; Special electric-conductivity and optical coatings deposition; New composite materials created from a steam phase; Producing of composition materials of nanocrystalline type based on copper, chrome, molybdenum, tungsten, carbon for all types of electrical contacts (sliding, arc-suppressing, gas discharge glowing). Producing the special metallic and ceramic powders for the thermo-spray and cold spray powdered coatings. Producing of targets for magnetron dispersion; Electron-beam re-melting, reduction, purification of metals and alloys; Design and mounting of the research and industrial equipment for mentioned above purposes; Today "ELTECHMASH" successfully cooperates with many companies in Ukraine, Russia, South Korea, China, Germany, Romania, Poland. The enterprise has modern equipment and highly skilled experts for any scientific and practical tasks solutions.

Front view of L-2 unit

K Halmesova

COMTES FHT a.s., Czech Republic

Title: Forging of Ti-Nb-Ta-Zr-O alloy –new material for hip implant

Time : 12:45-13:15

Biography:

Kristyna Halmesova has started her research in the field of thin films, now she works in applied research. She got a lot of experience in the field of magnesium alloys and their treatment. Now, she has begun to be one of the team that develops new biomaterial for hip implants. She has some experience in thermo-physical measurements.

Abstract:

Nowadays, the life time of hip joint implants is limited to 15-20 years which is not sufficient because of prolonged human lives and activity. This is due to a big difference in elastic modulus of an implant and a bone where the bone degrades in the area of non-loaded bone in a vicinity of too tough metal implant (stress-shielding). So the demand for new material for metal implants is increasing. The utilization of beta Ti- alloys is discussed in scientific literature for two decades. The advantages include using biocompatible elements and lower elastic modulus. A new developed beta titanium alloy (Ti-Nb-Ta-Zr-O) was prepared by sequential plasma arc melting but was prepared only in the as-cast condition. The main task is to specify and optimize the process of implant manufacturing. The current issue is to prepare the forging state of the alloy with sufficient fatigue resistance. Cold rotary swaging of this material with different degrees of deformation (40-80%) was successfully performed and recrystallization of the material was studied. Process optimization regime was selected and applied on bigger part of the material. Mechanical and fatigue properties were tested and were found to reach better results compared with the cast-state of the material.

Tau Chuan Ling

University of Malaya, Malaysia

Title: Crystallization and catalytic behaviour of cesium-based zeolite nanocrystals prepared in organotemplate free hydrogel system

Time : 14:00-14:30

Biography:

Abstract:

Zeolite is a widely used acidic catalyst in chemical reactions. However, large amount of strong acid sites of zeolite tend to over crack and produce coke, resulting in catalyst deactivation. Cs-zeolite has been proved to reduce coke formation and emerged as an excellent catalyst in base-catalyzed reaction for example, side-chain alkylation of toluene, cyanoethylation of alcohols, dehydrogenation of alcohols, deoxygenation of oxygenated-compounds, aldol condensation, O-alkylation of phenol, isomerization of alkenes, etc. Typically, Cs-zeolite is prepared by ion-exchanged with Cs+ ion or impregnated with Cesium oxide. Besides that, zeolites are typically synthesized with organic template which acts as structural directing agent (SDA). However, expensive price and associated environment issues with the combustion of templates are the major concern in the template-assisted synthesis of zeolites. Therefore, we aim to synthesize Cs-zeolite via hydrothermal method without addition of organic template and applied in Knoevenagel condensation.

Hwai Chyuan Ong

University of Malaya, Malaysia

Title: Conversion of microalgal biomass to biochar using thermochemical conversion

Time : 14:30-15:00

Biography:

Abstract:

Microalgal biomass is one of the suitable candidates for sustainable production of biofuels and other valuable green products such as biochar, biodiesel and bioethanol. Recently, microalgae are getting more research attention due to its applicability in biomass production and implications in carbon capture. Microalgae aid in the mitigation of greenhouse gases namely CO2 and this correspond to the reduction of global warming issue. With the high carbon fixing and photosynthetic efficiency, microalgae are beneficial for greenhouse gases emission reduction and simultaneous produce renewable feedstock for biofuels. Conversion of microalgal biomass into biochar is one of the approaches in context of bio-refinery where microalgal residue can be utilized for carbon sequestration or other applications. Thermochemical conversion, pyrolysis was used to produce a biochar yield of 26.9%. An alkaline pH value of microalgal biochar was determined and the H/C and O/C atomic ratios obtained were useful for application in carbon sequestration and soil. Microalgae biochar also revealed its potential as an alternative coal with the heating value of 23.42 MJ kg−1. The surface structure of microalgal biochar after pyrolysis can also be suggested for further application as bio-adsorbent. The production of microalgal biochar can be a potential approach towards microalgal bio-refinery for a sustainable environment.

Angelo La Rosa

London South Bank University, United Kingdom

Title: Determination of the monolayer coverage of silica particles

Time : 15:00-15:20

Biography:

Angelo La Rosa is pursuing his PhD in the School of Engineering at London South Bank University. Currently his research studies include in-depth comprehension of the mechanisms involved to graft the surface of the silica particles with tailored silanes. His PhD work is involved in Work Package 2 (WP2) of the EIROS European project which aims to fabricate advanced materials having anti-erosion and anti-icing properties through the incorporation of super hydrophobic silica particles as additive material into available-in-the-market-materials (epoxy resins or paints). The work is carried out into the National Structural Integrity Research Centre, a state-of-the-art postgraduate engineering facility established and managed by structural integrity specialist TWI.

Abstract:

Extreme weather conditions present significant challenges in several industrial sectors, such as automotive, wind energy, industrial cryogenics and aerospace. Passive solutions are important for achieving long term-functional performance. However, an effective, durable passive anti-icing or deicing surface has been yet to be demonstrated, indicating significant necessity for developments. Introducing enhanced chemical repellency and structured roughnesses into surfaces are two of the best candidates to achieve this main goal. Realizing these characteristics via the introduction of suitably functionalized silica nanoparticles represents an emerging approach that allows the modification of existing coatings and composite materials. Selective and specific functionalization of these silica particles is crucial in order to achieve a monolayer coverage avoiding partially covered particles or a surfeit of unreacted silane which may have undesirable impacts on the materials processing or ultimate properties. The primary aim of this study was to establish methods to determine the degree of functionalization and to identify the monolayer coverage of tailored silica particles. A model family of silica particles with diameter of approximately 35 nm was produced using a refined stober method. These silica particles were functionalized using hexamethyldisilazane (HMDS). Particle size analysis using dynamic light scattering methods was undertaken to determine the impact of functionalization on the average diameter and size distribution within the suspension. Drop Shape Analysis (DSA) was used to evaluate the repellency of a dried film of the functionalized silica particles deposited onto a glass slide. As the degree of functionalization increases, the repellency of the film also increases to a maximum value followed by a plateau where increasing silane has little impact on the repellence. Thermogravimetric analysis was also used to assess the weight loss versus the grafted silane onto the surface of the silica particles. This info provided an indication at which point the monolayer coverage of the TWI silica nanoparticles grafted with HMDS can be inferred. This study provides the underpinning approach that allows the establishment of monolayer coverage and optimization of the coacervation of silica particles.

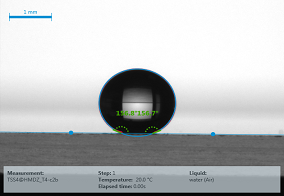

Figure: Image of a super hydrophobic coating using a Krüss 100 DSA

Elbeshary A A Mohammed

Ghent University, Belgium

Title: Lead dodecanoate coating for the corrosion inhibition of lead heritage objects: A comparison between aqueous and ethanolic coating media

Time : 15:20-15:40

Biography:

Elbeshary A A Mohammed is a PhD student in the Department of Chemistry at Ghent university, Belgium. He obtained his bachelor’s in chemistry from the Faculty of Science, South Valley University, Egypt. Afterwards, He obtained a Master in Electro-Analytical Chemistry from the same university. Then, He worked as a R&D Chemist at the Egyptian Sugar and Integrated Industries Company (ESIIC), Egypt. After that, He got a scholarship from the European Commission to study PhD in Chemistry at Ghent University, Belgium. His PhD focuses on the development of environmentally friendly coatings for the corrosion inhibition of metallic lead and iron cultural heritage objects.

Abstract:

Lead metal has been used in many applications in ancient times because of its high density and ease of casting due to its low melting point. Some of these applications are for water piping, statues, roofing, weights, coins, and pipe organs. Many of those objects are exposed to atmospheric conditions and are shown in open museum showcases, where it is difficult to be in full control of the environment. Therefore, they corrode and are naturally covered by corrosion products. The most common corrosion products found on lead metal surfaces are litharge (PbO), anglesite (PbSO4), and hydroxy carbonate compounds such as cerussite (PbCO3), hydrocerussite (Pb3 (CO3)2(OH)2), or plumbonacrite (Pb10(CO3)6O(OH)6). However, those corrosion products do not cover the surface sufficiently to protect the lead metal. One way to avoid or at least delay the corrosion is by using protective coatings. In this work we use aqueous and ethanolic dodecanoate solutions to synthesize a hydrophobic lead dodecanoate coating (Pb(C12)2) . This coating works as a barrier preventing access of corrosive substances to the lead metal surface. The coating is made by immersing a set of lead substrates, separately in aqueous sodium dodecanoate solutions. Another set of lead substrates have been coated by immersing them in ethanolic solutions of the dodecanoic acid. The coating formation has been confirmed using FTIR spectroscopy and SEM techniques. The protective properties of the coatings have been studied in an ASTM D1384-87 solution by the use of linear sweep voltammetry (LSV) and electrochemical impedance spectroscopy (EIS). The coatings provided from the aqueous solutions demonstrate better protective properties against lead corrosion comparing to that obtained from the ethanolic solutions.

Pon Janani Sugumaran

National University of Singapore, Singapore

Title: Ferromagnetic nanoparticles – A tool for high performance magnetic hyperthermia

Time : 15:55-16:15

Biography:

Pon Janani Sugumaran is pursuing her PhD in the Department of Materials Science and Engineering at National University of Singapore under the supervision of Prof Ding Jun. She has completed her Master’s in Nanotechnology. The main objective of her doctoral studies involves synthesis and surface functionalization of Iron oxide nanoparticles for biomedical and environmental applications. The aim was to develop a multi-functional, bio-compatible, stable and good magnetic responsive nanocomposite for magnetic hyperthermia cancer treatment.

Abstract:

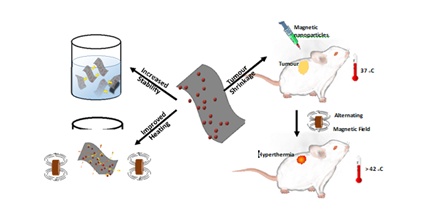

Cancer is the second prominent cause of death worldwide, with approximately 9.6 million deaths in 2018. The mortality can be reduced if the cases are detected and treated in earlier stage. Existing treatment methods such as surgery, chemotherapy and radiotherapy can cause side effects like organ dysfunction, non-specificity, inflammation and they are non-localized. Magnetic nanoparticles (MNPs) tend to oscillate and dissipate energy in the form of heat when they are exposed to an alternating magnetic field, resulting in rise in local temperature. This property of localized heating is employed in magnetic fluid hyperthermia (MFH) for cancer treatment, in which the MNPs at the tumor site increase the temperature to 42-46oC, which denatures the proteins and affects the cell viability. MNPs can be targeted to tumor site by attaching with a suitable ligand which selectively binds to the tumor cell receptors and kills the cancer cells, without affecting the normal cells. The efficacy of MFH is higher compared to that of the conventional radiotherapy and chemotherapy. The synthesis of a MNP with good magnetization, biocompatibility and stability is important for MFH. The size, shape, composition, inter-particle spacing, confinement and surface functionalization are found to affect the surface absorption rate (SAR) of MFH. Superparamagnetic (SPM) particles of size <15 nm are commonly employed due to their good colloidal stability. Recent studies show that large MNPs have good magnetic response due to large hysteresis area and high magnetic saturation (Ms) and contribute to higher SAR values. They could heat-up the tumor site faster with a relatively smaller concentration of particles, low frequency and applied field compared to the SPM particles. But their usage is restricted due to their poor colloidal stability. This work addresses on the development of a universal carrier using Graphene oxide (GO), which could aid better colloidal suspension irrespective of the size or shape of the particle. We have developed a novel magnetic nanotube-GO nanocomposite, which could be stable even in biological environment and a high SAR value of 4322 W/g was obtained for a frequency of 400 kHz and applied field of 32 kA/m. The calculated Intrinsic Loss Power is 11.6 nH m2 kg-1, which is one of the highest reported value. The Nanotube-GO composite showed good biocompatibility in vitro and in vivo and has shown excellent anti-tumor efficacy in 4T1- tumor model mice by inhibiting their progression within a safe dosage range. The availability of functional groups in GO can be exploited for tagging and employed in targeted delivery.

Dilip Krishna Nandakumar

National University of Singapore, Singapore

Title: Harnessing ambient humidity for energy conservation, harvesting and environmental applications

Time : 16:15-16:35

Biography:

Dilip Krishna Nandakumar has completed his Graduation at National Institute of Technology, Tiruchirappalli, India in Metallurgical and Materials Engineering. He is currently pursuing his PhD in the Department of Materials Science and Engineering at National University of Singapore. His research focusses primarily on the synthesis of novel materials for harnessing non-conventional sources of energy. The primary goal of his research is to utilize ambient humidity as a potential source for sustainable water production, energy conservation and integration of photosystems for direct electrical energy harnessing from ambient humidity.

Abstract:

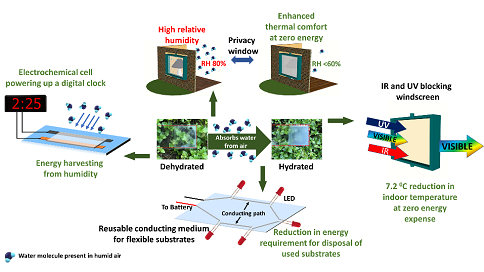

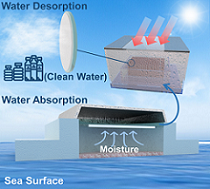

Ambient humidity is ubiquitous and is widely considered a redundant resource demanding an additional expense of energy to maintain it at thermally comforting levels. With research on alternative sources of energy primarily blinkered towards transduction of solar, wind, tidal and other forms of ambient energy sources directly into electrical signals, a holistic approach to harness the omnipresent humidity is relatively scarce. The earth’s atmosphere has a staggering 13 trillion kiloliters of water, which can be utilized for various energy and environmental applications. Conventional hygroscopic materials do not offer a sustainable route in utilizing humidity as they suffer from low water uptake and high energy requirement for water release. Intrigued by these challenges, we have developed a novel super-hygroscopic hydrogel with water absorption capability over 4X its own weight and ultra-low temperature of water release. The synthesized hydrogel exists in two distinct states hydrated (H) and dehydrated (DH) depending on the level of relative humidity (RH). The hydrogel displays interesting humidity-triggered changes in optical, electrical and electrochemical properties that were exploited for energy conservation applications. We have developed proof-of-concept models to demonstrate the energy conservation applications in the form of a thermo-hygroscopic privacy window that operates at no energy expense, an infrared radiation blocking windscreen that aids in reducing heat buildup inside rooms leading to mitigated air-conditioner usage, a conductive medium for reusable flexible electronic substrates and an electrochemical cell for energy generation. Additionally, we have also developed a novel solar energy triggered technique to pull clean water from the sea by exploiting the humid air space that exists above sea surface. Through multiple absorption-desorption cycles, it is currently possible to harvest up to 14L of clean water per day per kilogram of the hydrogel used. This method opens-up new possibilities for contact-less desalination approaches in the near-future.

Srijita Nundy

Sungkyunkwan University, Republic of Korea

Title: Highly selective and sensitive distinct flower-like ZnO microstructure based gas sensor with optimized CTAB concentration for detection of NOx at room temperature

Time : 16:35-16:55

Biography:

Srijita Nundy has completed her BS and MS degrees in Physics at Calcutta University and Shoolini University in India respectively in 2015. Since 2015, she has researched on ferromagnetic material synthesis and application at Chung Yuan University, Taiwan and worked as a Physics Researcher in Onnuritech, Seoul, Republic of Korea till 2017. Currently, she is pursuing her PhD studies on nanomaterial synthesis and device fabrication for application in various fields of biosensors and metal oxide based gas sensors at Advanced Material Science Engineering (AMSE) department at Sungkyunkwan University, Suwon, Republic of Korea.

Abstract:

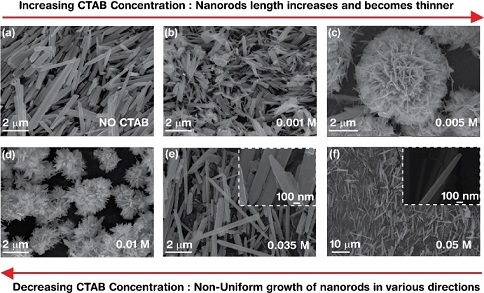

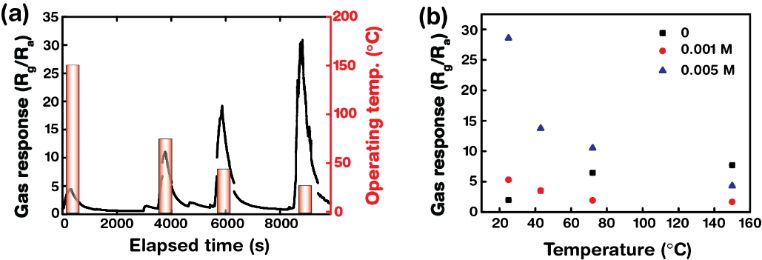

Nitrogen oxide (NOX) is considered as toxic molecule giving harmful influences not only on human body, but also on environment. Thus, to detect NOx, here, in this article we report hydrothermal synthesis of different morphologies of ZnO with gradual increase of CTAB concentration forming nano rods (0M), nano rods assembled structure (0.001M) to flower-like (0.005M) and studied morphology dependent gas sensing behavior to NOx gas at low temperature. The characterizations of the as-prepared samples were done in details by X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray photoelectron spectroscopy (XPS), Raman spectroscopy, photoluminescence (PL) spectroscopy and Brunauer-Emmett-Teller (BET). The gas sensing performance of sensors fabricated with as-prepared ZnO structures to various concentrations of NOX, ammonia, toluene, carbon-monoxide, acetone and ethanol, at various operation temperatures (25 to 150°C) were noted. A clear trend showing effects of the morphology on the sensing behavior with temperature was demonstrated. The flower-like ZnO exhibited stability (up to 140 days) and excellent sensitivity with a high gas response of 29 which drops sharply with increase of temperature and is highly selective towards 0.74 ppm of NOX at 25 °C without additional use of UV irradiation or doping materials such as Pt or Pd. The ZnO sample with 0.001M of CTAB shows a similar trend but with much lower sensitivities at low temperatures. For the sample without CTAB, the temperature behavior switches to a volcano-type one, in which the sensitivity is low at a low temperature and increases gradually with the temperature increasing. Thus, we proposed possible reason for the evolution of overall characteristics by suggesting changing reactions between ZnO and reacting gases in various operating temperatures.

Figure 1: Effect of CTAB concentration variation (no CTAB, 0.001M, 0.1M, 0.35M and 0.5M) on the morphology of the ZnO microstructures for the formation of FZO.

Figure 2: Sensing response of (a) 0.005 M CTAB concentration sample and of (b) samples of all concentration variations of NOX gas (0.74 ppm) with different operating temperatures (25°C, 43°C, 72°C, and 150°C).

- Poster Presentations

Location: Foyer

Session Introduction

Suzana Polić

Central Institute for Conservation, Serbia

Title: Materials science and zeitgeist as a basis for the preservation and restoration of cultural heritage

Biography:

Abstract:

Modern conservation the restoration of art objects is followed by research in the field of material science. The application of diagnostic methods and reversible procedures in this field is a Zeitgeist scientific methodology, since the material of the original artwork, or a unique archaeological object, requires an exclusive approach. In this sense, the experimental works are performed on materials of the equivalent composition, with the inclusion of the chain of previous influences on objects of cultural heritage. In this paper the triangle is studied: material sciences, conservation and restoration and zeitgeist with a chain of previous influences. In this way, material science is viewed in the context of a multidisciplinary approach to heritage protection.

Suzana Polić

Central Institute for Conservation, Serbia

Title: Materials science and zeitgeist as a basis for the preservation and restoration of cultural heritage

Biography:

Abstract:

Modern conservation the restoration of art objects is followed by research in the field of material science. The application of diagnostic methods and reversible procedures in this field is a Zeitgeist scientific methodology, since the material of the original artwork, or a unique archaeological object, requires an exclusive approach. In this sense, the experimental works are performed on materials of the equivalent composition, with the inclusion of the chain of previous influences on objects of cultural heritage. In this paper the triangle is studied: material sciences, conservation and restoration and zeitgeist with a chain of previous influences. In this way, material science is viewed in the context of a multidisciplinary approach to heritage protection.

Kateřina Mertová,

COMTES FHT a.s Czech Republic

Title: Investigation of mechanical properties using miniature specimens on additive manufactured Ti-6Al-4V

Biography:

Katerina Mertova is working at Comtes Company in DobÅ™any. She is working as a Research Scientist in the Department of Mechanical Testing. At Comtes Company they provide everything from the standard testing such as tensile, compression or bending tests, and fatigue or fracture toughness tests to specialties at the customer’s request. Her strengths are in handling responsibility, thoroughness and reliability. She focuses on biomaterials and 3D printing.

Abstract:

In the scope of this paper, the usage of the miniature samples and investigating using small samples is discussed. The miniature samples were used for determination of mechanical properties for titanium alloy deposited by additive manufacturing. The tensile tests on the standard and the miniature samples were provided for commonly used Ti-6-Al-4V alloy. These titanium alloy samples were produced by electron beam melting and by selective laser melting method that belongs to powder bed fusion processes of 3D printing. The purpose of this work was to demonstrate that local material characteristic can be obtained using the miniature specimen. The usage of small samples could provide many advantages for testing of mechanical properties. In our investigation it is shown that the results are in good agreement for standard and miniature specimens. The strength characteristics reached identical values. However, the plastic characteristic, such as elongation and reduction of area, are not comparable duo to the presence of internal defects. The small defects, such as lack of fusion or pores, have major impact on the miniature samples in comparison to the negligible influence on the larger specimens. The fractography included in this research reveals the differences for the small and standard size specimens.

Athar Safari

Brandenburg University of Technology, Germany

Title: Investigation of high temperature cyclic loading behavior of molybdenum-hafniumcarbide

Biography:

Athar Safari has her expertise in Materials Science and Engineering. With respect to her background on high-temperature mechanical behavior and creep properties of metallic alloys, she is dealing with the possibilities to increase the service life, hardness, heat resistance, application temperatures and damage resistance of materials used as die forging tools for high-temperature forming of Titanium Aluminides.

Abstract:

The isothermal forging of titanium aluminides takes place between 1100°C and 1250°C with very low strain rates. This requires materials for the forming tools which have high stability at elevated forming temperatures as well as high resistance against wear, good oxidation resistance and heat resistance. At present, forging dies made of molybdenum alloys, which enable the shaping of titanium aluminide materials in an isothermal forging process, are used. Particle-reinforced molybdenum-hafnium-carbon alloys (MHC) exhibit a sufficiently high yield strength at 1200°C and a much better heat resistance than nickel-base alloys, iron aluminides or high-strength steels. Further progress in the development of new titanium aluminide alloys requires advanced forging tools and thus more knowledge about the tool material. Despite the great potential and application technological acceptance of MHC in high temperature applications, the thermo-mechanical behavior of this alloy with special focus on alternating load is not completely understood. Considering the forging process as a high temperature long-term low cycle fatigue process, in this study the mechanical behavior of MHC was investigated after several cyclic loading patterns. The tests were performed under different stress levels and different speed conditions. Microstructural observations, using optical microscopy and secondary electron microscopy were carried out. Hardness measurements were performed before and after cyclic loading in different conditions. The results show a decrease in the number of cycles until sample failure with increasing level of applied stress and an increase in the number of cycles until failure with increasing velocity.

Biography:

Gregory Lacoste has his expertise in mechanical testing of aeronautical materials and structures. He has specialized in high temperature tests for the characterization of materials evolving in extreme conditions such as turbomachinery. He is also specialized in video measurement (digital image stereo correlation and in situ image analysis).

Abstract:

Biography:

Manuel F Azamar has completed his Bachelor's degree in Mechanical Engineering at Instituto Tecnologico de Veracruz, in 2016. He has completed an internship for one year at the Research and Development Center of Tenaris Tamsa, Veracruz, Mexico in the Departments of Materials, Metallurgy and Welding Technology analyzing the parameters of different welding processes applied to seamless steel pipes and its impact in mechanical properties. Currently he is pursuing his Postgraduation in Materials Science in the Instituto de Investigaciones en Materiales at UNAM, Mexico City, Mexico.

Abstract:

Metallic foam is a porous media that combines physical and mechanical properties, such as a low specific weight with high compression strength. Since pores are interconnected, foams have the capacity to conduct fluids, reason why represent an option in engineering. The objective of this research is to investigate the permeability behavior of aluminum foams with different pore sizes simulating pressure and temperature conditions of reservoir, with the aim of evaluating its performance as an alternative for oil and gas industry. The methodology followed consisted in the preparation of aluminum (Al) foam samples with different pore sizes. This was carried out by means of infiltrating an open pore bed of bonded sodium chloride (NaCl) particles with molten Al, and then leaching the NaCl in distilled water. The wall thickness among the pores was measured and porosity percentage was calculated using a helium pycnometer. The compressive behavior of the foams was determined using an instron universal testing system, for obtaining young's modulus and compression strength. Finally, with the Darcy's law, the permeability coefficient of the samples was calculated by oil flux with high pressures intervals at room temperature, 100ºC and 200ºC. The importance of this project is that metallic foams for the energy industry have never been investigated nor proposed, thus the results presented in this research give way to a new engineering application of this materials.

Biography:

Aleksandra Debowska is pursuing her PhD at AGH University of Science and Technology. Currently, her area of research interest includes scientifically high temperature corrosion science and alternative energy sources. She graduated in chemistry with forensic and conservation chemistry specialization from Jagiellonian University, Cracow, Poland.

Abstract:

The choice of material used to work at high temperatures is one of the main problems while designing equipment for energy applications. Additionally, the presence of such elements as S, Cl, K or Na (typical elements which may be find at biomass or municipal wastes) in the work environment increases the possibility of corrosion occurrence. The aim of this study was to investigate the surface and cross-section of weld cladded (CMT, Cold Metal Transfer method) samples of Inconel 625 after exposure to different renewable fuel ashes at 650 °C for 500 h. Characterization of the Inconel samples and ashes after the corrosion process was performed using scanning electron microscopy (SEM) with EDAX analysis, X-ray fluorescence (XRF) and X-ray diffraction (XRD). Figure 1 shows cross-sectional image of Inconel sample after the corrosion process caused by mixed wood ash. On the surface, the corrosion products can be distinguished mostly oxides of elements such as chromium or nickel. Moreover some ashes compounds were observed as residues. There was proved that the effects of corrosion process depend on the type of ash used.

Remigiusz BÅ‚oniarz

AGH-UST, Poland

Title: Effect of thermomechanical processing on dynamic behavior of HSLA steel

Biography:

Remigiusz Bloniarz is pursuing his PhD at AGH University of Science and Technology. He is scientifically interested in behavior of materials under dynamic loading conditions, advanced thermo mechanical processing and manufacturing technologies. He was awarded by Honorable Mention in TMS Bladesmithing Competition student competition accompanying by TMS Annual Meeting & Exhibition in 2015.

Abstract:

Micro alloyed HSLA steel was subjected to advanced thermo mechanical processing. The unique combination of processing parameters and microstructural phenomena i.e., combined metal forming consisted of cold rolling and subsequent thermo mechanical rolling, recrystallization and precipitation processes during reheating allow to study the role of prior austenite morphology in the development process of ultrafine grained and bimodal microstructures. Produced in the thermo mechanical processing material was analyzed and characterized using optical metallography, Electron Back Scattered Diffraction (EBSD), Scanning Electron Microscopy (SEM), and X-ray Diffraction (XRD). The results show a clear effect of the paths of thermo mechanical treatment on microstructure development and mechanical response of produced in such a way micro-alloyed steel specimens. The investigated specimens were subjected to the compression and tension tests under quasi-static and dynamic loading conditions. In these tests a wide range of strain rate was applied to demonstrate the ability of the investigated inhomogeneous microstructures to accommodate the deformation effects under dynamic loading conditions. It has been shown that produced in the thermo mechanically processed specimens complex microstructures effectively inhibit nucleation of the stress concentrations. It was observed that the deformation energy dissipates on the interphase boundaries due to the differences in mechanical response of the microstructure components.

Mingyu Song

Inha Universitiy, South Korea

Title: MOF based Fe2O3 hollow Nano cube @ Graphene oxide-Ni for toxic gas sensor

Biography:

Mingyu Song has completed his Bachelor’s degree in the field of Chemical Engineering and started his study on graphene-based materials especially for toxic gas sensors and capacitors. He has won several competitions and won several prizes for his innovative design in engineering during his college days and also in International appropriate technology design competition. Currently, he is working on his paper about toxic gas sensor.

Abstract:

Graphene has been considered as a promising candidate for gas sensor since its high surface area, conductivity and sensitivity to its surroundings which are attributed to its unique 2D structure and conjugated carbon system. However, graphene should be functionalized to assign selectivity and higher response to bare graphene. On the contrary, metal oxide gas sensors have been reported as high responsive and selective sensors, but its operating temperature is usually higher than 150º C which is not suitable for our daily lives. In this regard, our research groups convert graphene oxide into nickel functionalized graphene oxide composite with Fe2O3 hollow nano-cube for toxic gas sensor at room temperature for synergistic effect of them. As prepared materials were characterized by scanning electron microscope, transmission electron microscope, X-ray diffractometer and gas sensor test system. We found that functionalized graphene oxide has better selectivity and response to formaldehyde gas among ammonia, trimethyl ammonia and formaldehyde gas. Consequently, response of as-prepared sensors is improved by adding iron oxide hollow nano cube. Also, it shows optimum annealing temperature at 300º C in terms sensor performance. The enhanced performance is attributed to the characteristics of nano cubes which have superb adsorption property and ability to prevent aggregation of graphene. Among three toxic gases, the sensor showed the highest response to formaldehyde gas.

Myeong Yeon Lee

Inha Universitiy, South Korea

Title: Preparing PEI-silica hybrid gel by sol-gel method

Biography:

Myeong Yeon Lee is a Chemical Engineer and has completed his Bachelor’s degree from Inha University. He has started his research on silica aerogel materials for thermal insulation. He has enthusiasm with cognizing problem, problem solving and giving profits to the people. He is pursuing his Master degree from Inha University. Currently, he is working on his paper about thermal insulation.